How to Compare Sun Tunnels? How to recognize what a sun tunnel brings you?

For a normal customer it is difficult to recognize why a sun tunnel should be 20% cheaper than a real sun tunnel which causes no embarrassment or worry neither to its producer nor to the person who chooses it for their home.

Why are Lightway crystal sun tunnels more expensive than the competition?

Roof dome are made from Bohemian Crystal and practically don’t age compared to plastic domes. Crystal has great capacity for collecting daylight when there is cloud cover. Crystal domes don’t distort the natural colors of daylight. The surface of crystal is very hard and smooth and smog and dust doesn’t stick to it as on plastic. Crystal domes don’t yellow after several years on a roof and continue to emit light for decades. The surface of the dome is perfectly washed with each rain because smog and dust are not baked on as with ordinary plastic domes.

When water leaks from a sun tunnel on cold days and leads to heat loss in winter, and in summer, conversely, there is a lot of heat in the space.

This feature is not comparable with anything on the sun tunnel market. It has been patented by Lightway as a feature directly connected to the heat insulation of the building at the access point of the tube and prevents the development of water condensation in the sun tunnel, loss of heat in winter months and excess heat gain in summer months. Other producers use a so-called double diffuser, which is ineffective as it is not connected at the point of heat insulation and doesn’t interrupt the thermal bridge of the aluminum tube. Some use a double dome with the assumption that it solves the problem. The dome is not connected to the heat insulation and the thermal bridge again develops. This is only an advertising move for people who are unable to recognize because they aren’t specialists. Some producers put a transparent plastic partition inside the tube and claim that it breaks airflow and thus prevents water condensation. According to the laws of physics, it is not possible to interrupt air current at joints larger than 18mm. This producer puts this plastic partition 30cm above the diffuser. In reality it is actually only a lid against the flow of water onto the diffuser so that it is hidden from customers’ eyes and he is not shocked that the tube is full of water, which is actually happening with his sun tunnel.

Diffusers – Spreaders of light throughout the room

Lightway chose sodium-potassium glass for the ceiling diffusers of incoming light. Other producers make this feature from plastic, which means faster aging and the danger of color distortion in the incoming daylight. There is a difference visible to the eye between plastic and glass diffusers.

Comparison of varieties of sun tunnels in use

Generally, there are 3 kinds of reflective surfaces for the tubes. In them we distinguish various reflective layers which attempt to direct the flow of daylight. It is the most important component of a sun tunnel and, depending on the type of tube, we can know what to expect as a result, and if the sun tunnel delivers enough daylight and quality daylight and also how long it will deliver it.

The following basic characteristics of sun tunnel tubes are evaluated:

- Amount of Delivered Light: we measure its sufficiency in the lit space, even when it is e.g. winter and cloudy.

- Light Quality: its spectrum of color and movement throughout the room. The tube must not alter such valuable characteristics of daylight. In such a case, it would be better to light the space with a lamp or energy-saving light bulb.

- Tube Lifetime: here we evaluate how long we want a sun tunnel, and how, over time, its performance and quality changes the light entering the room.

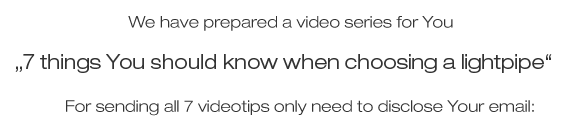

Flexible tube

How to recognize it? The material reminds you of an accordion, it is composed of laminates which are fixed with aluminum foil and the tube is not rigid.

- Amount of light: due to physical laws, it delivers very little light. For this kind, the name “dark tunnel” has been created. Construction companies like to use it as a substitute for a sun tunnel because its price is a third of a sun tunnel which shines. It works only in direct sunlight.

- Quality of Light: sunlight in the tube quickly breaks down into many small rays and the full spectrum of sunlight is not delivered. The lit surfaces in the room are then color-distorted.

- Lifetime: aluminum foil ages under the influence of UV rays, but the customer doesn’t recognize this. This type doesn’t perform even from the beginning just after being installed in the building.

- Price: the cheapest product on the market. It is mainly manufactured in USA and Poland. The price is a third of a sun tunnel which shines.

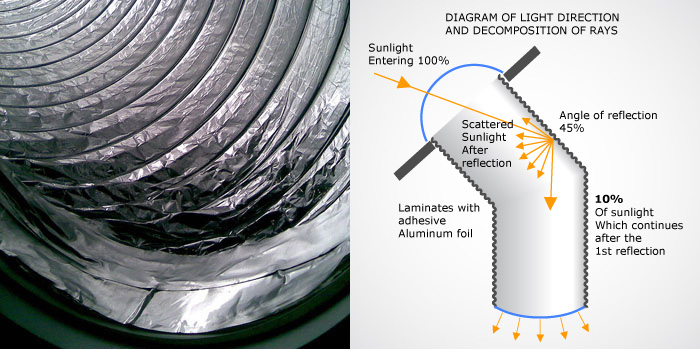

Tube with an Adhesive Reflective Foil on an Aluminum Surface

How to recognize it? Ask a supplier if the tube has a reflective layer created from a sticker, lamination or otherwise affixed reflective foil. As well, look at the surface in the light personally. If you can make out a subtle orange-like structure of the reflective surface, it is this type described here. Producers present a high reflectivity of 99.7%. So what’s the catch?

- Amount of Light: producers claim a reflectivity of 99.7%. Directional reflectivity below an impact angle of 45 degrees, for sunlight directed into the room in the tube according to laboratory tests is a mere 50%!!! These angles of ray impact on the reflective layer of the tube are typical for a sun tunnel and gauge its capacity to actually deliver sunlight. Why does this happen? Why does the surface have a measurement of 99.5% at angles below 90 degrees? And below 45 degrees only 50%? Physical laws strike again; when you look at the reflective surface of the tube below an angle of 45 degrees and against the light, you see an uneven surface, an orange-like structure which develops when sticking the reflective foil onto the aluminum tube. What does this cause? When reflecting, half the light breaks down into many smaller rays which don’t have the strength anymore to continue down the tube and are lost before they can enter the room and there is a lack of light in the space.

- Quality of Light: just after being installed in the building it delivers the sunlight spectrum with high quality. After a time the reflective surface begins to age and change color. It is neither resistant to UV rays nor humidity. This remarkably lessens the amount of sunlight delivered into the room. The color fidelity of sunlight is lost with time and begins to emphasize some colors, which negatively effects the color expression on surfaces which are lit by such a sun tunnel. Thus the sun tunnel’s main purpose is lost in view of the human eye and psyche, i.e. providing human vision sufficient real sunlight.

- Lifetime: reflective foil has very low resistance to UV rays and otherwise doesn’t withstand the very common temperature changes and amount of humidity in the tube. When something is glued to an aluminum surface it has a limited lifetime and a tendency to become unstuck and form bubbles on the surface. Laboratory tests reveal very low endurance for UV radiation, in practice mainly type UV-A, and causes surface coloring and mainly a lowering of its reflectivity. The reflective surface of this tube then becomes the weakest and most at-risk place of this kind of sun tunnel.

- Price: due to the very low price of reflective foil and the common practice of laminating to the aluminum surface, the price of this type of sun tunnel is about 30-40% lower in comparison with the price of the highest-quality sun tunnel. These kinds of sun tunnels are produced in the USA.

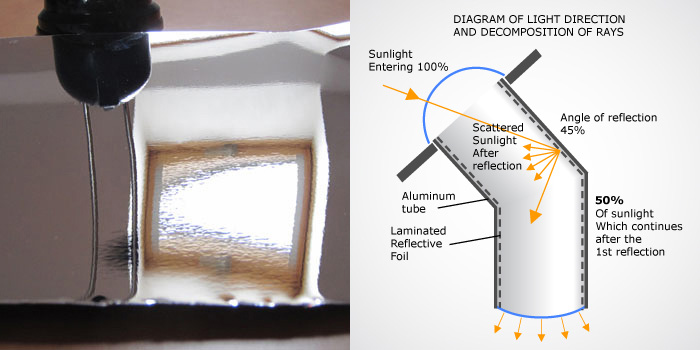

Tube with Mirrored Reflective Surface Produced by the Technology: Chemical Vapor Deposition in a Vacuum.

How to recognize it? The reflective surface of the tube, under all angles and against the light, is clear and clean like a mirror.

- Amount of Light: the most productive sun tunnel system on the market to date. In the most important test of directed reflectivity of sunlight rays at an angle of 45 degrees, the surface of the tube reflects 98% of the light. Then the absolute majority of the light continues on through the tube and into the room and provides plenty of sunlight even in winter under cloudy skies. And this is even in cases where the tube is dozens of feet long and making turns.

- Quality of Light: the reflective surface faithfully delivers and doesn’t distort the colors of the sunlight spectrum nor distort colors on surfaces in the lit space. Daylight delivered through this tube also fulfills hygienic required norms for lighting buildings. The human eye positively perceives quality sunlight and it reduces the development of health complications from a lack of sunlight in a building.

- Lifetime: the guarantee on the mirrored surface is 25 years. It is resistant to all types of UV rays, high humidity and common exchanges of high and low temperatures in the sun tunnel. The reflective surface is produced by demanding technology, where, due to chemicals and heated plasma, the adhesive material becomes vapor, and in a vacuum it is sprayed by an electronic canon and adheres to the polished surface of the aluminum tube, forming micro-layers. To date there is no higher-quality industrially-produced reflective surface and is scientifically and technically cutting-edge.

- Price: the most expensive type of sun tunnel on the market. Its price is 20-30% higher than average sun tunnels. Lightway is a producer from the Czech Republic and has been engaged in production since 1999.